Predictive Maintenance

General description

Both, plant control and operation in modern industrial companies are usually very complex. Many work steps are automated and performed by robots. In this automated environment, the price of an error is very high, as it can lead to damage to several products at the same time and expensive production interruptions. Incalculable reactive maintenance of their equipment can be difficult for companies to afford. Maintenance intervals are cost-intensive, but without maintenance the probability of failure increases significantly. However, machine parts with high wear and tear can be detected and quickly replaced or repaired.

In this context, modern companies demand not only real-time monitoring and analysis of problems, but also a direct answer to the question "When and where will the next undesirable event or irregularity occur and how can we remedy it?" It's all about nothing less than future-proof predictive operation of machines and systems while reducing downtime and maintenance costs.

Solution overview

Compared to Operational Analytics, which deals with monitoring and alerting, Predictive Maintenance analyzes historical data with the aim of making forecasts of critical operational events. Thus, our "Predictive Maintenance" solution is an intelligent, future-oriented extension to "Operational Analytics".

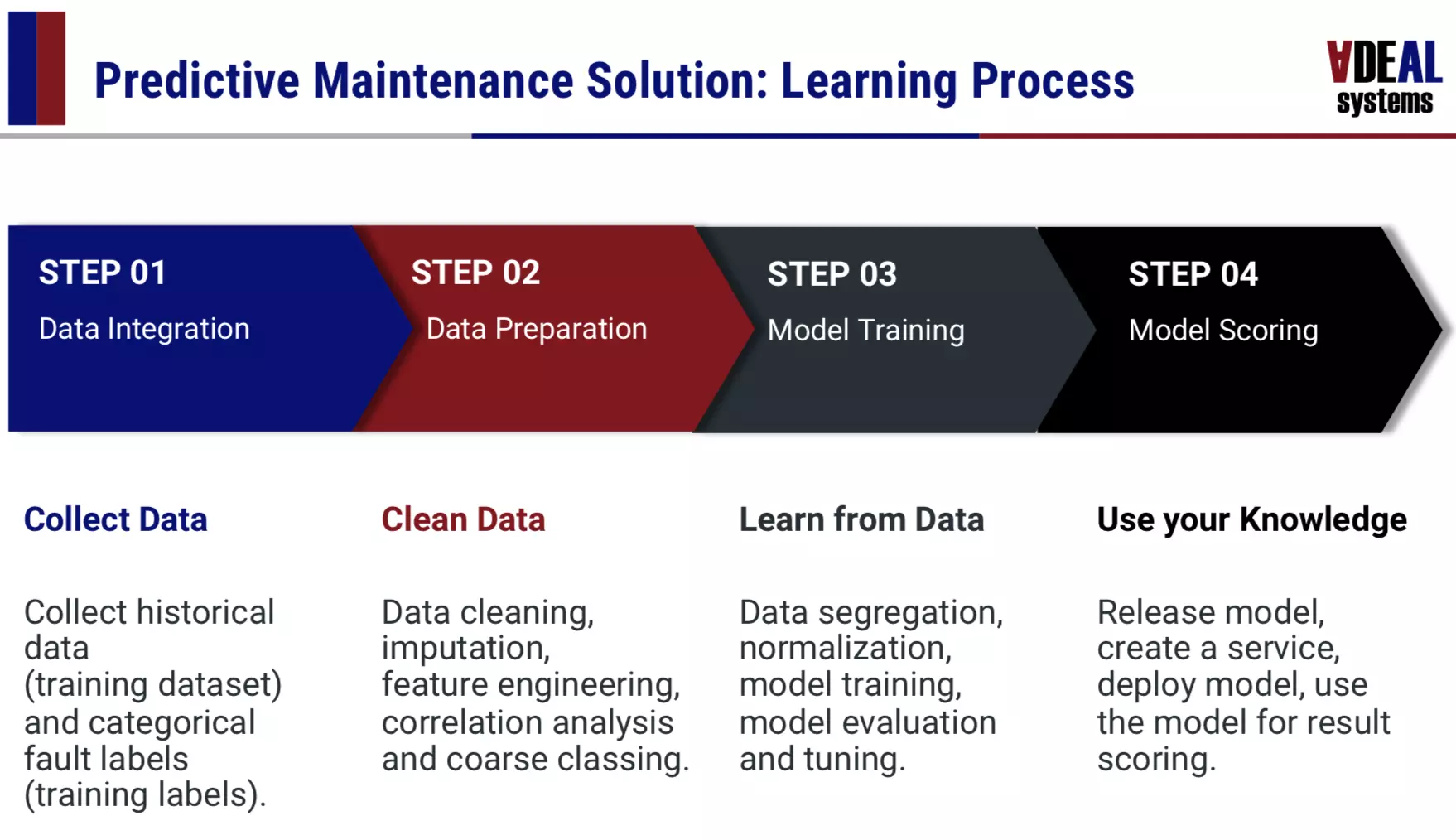

Using modern data mining and machine learning methods, the data is prepared, correlated and classified. Predictive models are trained and validated. The tested and validated models are then published accordingly as cloud services and made available to end users and IT systems. At the end of this chain, each company receives a model-based forecast of errors and failures, predictions of useful life and operating and maintenance times. In addition, concrete advice is given on the most critical wear parts.

We regard our Predictive Maintenance solution as an integral part of the production cycle of companies. It monitors material conditions and makes recommendations for maintenance and repair work on industrial plants and their components.

Your benefits

Our solution significantly increases the efficiency of production processes in companies. Downtimes and production stops are minimized and the availability of production facilities is maximized. This increases the quality of work and saves maintenance costs. We make your plants smarter and more durable, ready for the future!

Both, plant control and operation in modern industrial companies are usually very complex. Many work steps are automated and performed by robots. In this automated environment, the price of an error is very high, as it can lead to damage to several products at the same time and expensive production interruptions. Incalculable reactive maintenance of their equipment can be difficult for companies to afford. Maintenance intervals are cost-intensive, but without maintenance the probability of failure increases significantly. However, machine parts with high wear and tear can be detected and quickly replaced or repaired.

In this context, modern companies demand not only real-time monitoring and analysis of problems, but also a direct answer to the question "When and where will the next undesirable event or irregularity occur and how can we remedy it?" It's all about nothing less than future-proof predictive operation of machines and systems while reducing downtime and maintenance costs.

Solution overview

Compared to Operational Analytics, which deals with monitoring and alerting, Predictive Maintenance analyzes historical data with the aim of making forecasts of critical operational events. Thus, our "Predictive Maintenance" solution is an intelligent, future-oriented extension to "Operational Analytics".

Using modern data mining and machine learning methods, the data is prepared, correlated and classified. Predictive models are trained and validated. The tested and validated models are then published accordingly as cloud services and made available to end users and IT systems. At the end of this chain, each company receives a model-based forecast of errors and failures, predictions of useful life and operating and maintenance times. In addition, concrete advice is given on the most critical wear parts.

We regard our Predictive Maintenance solution as an integral part of the production cycle of companies. It monitors material conditions and makes recommendations for maintenance and repair work on industrial plants and their components.

Your benefits

Our solution significantly increases the efficiency of production processes in companies. Downtimes and production stops are minimized and the availability of production facilities is maximized. This increases the quality of work and saves maintenance costs. We make your plants smarter and more durable, ready for the future!